Back in the Summer of 1999, Pat Green and Troy Holmes first crossed paths while working together as Automation Engineers. Pat was 31 at the time, having worked 5 years in robot and PLC programming as an Electrical Controls Systems Designer.

Troy on the other hand was 23, still in University, and working on trying to create a market for paint robots in Australia after his stint with Ford Motor company. Pat had a career progression opportunity, and went onto to become a Robotics Division Manager, while Troy completed his university studies, and went to work in the US for what was FANUC Robotics America at the time. While Pat was busy managing a robotics division for the next 2 years, Troy continued to travel back and forth between the US and Australia, with the paint robot business in Australia growing exponentially across a multitude of different OEM’s and Tier 1’s. The two continued to keep in contact primarily via SMS and email, sharing a common interest in light-hearted humour.

Automated Solutions Australia (ASA) was conceived as an idea back in 2002, and by July of that same year, it had been registered as a company. The idea was to be a specialist company in paint robotics, as many other rival automation companies considered paint to be a bit of a black box of sorts. Paint is far more focused on the overall system, and maintaining ideal spraying conditions, whereas your typical robot programmer is focused more on AND and NOT statements in programs, and picking or placing, or welding, fixed points. Paint has far more variables, and the robots have to be purpose built to operate in Class 1, Division 1 environments, so it is very much a specialist niche area of robotics.

The two of them discussed setting up, one in Adelaide, and one in Melbourne, to service the customer bases in those cities accordingly. They put trust in one another’s abilities, as neither had ever run a business in their own right at the time. Initially, it would be the two of them, attending breakdowns, and providing support to customers, in what they framed as “Automated Facilities Support Agreements”, or AFSA’s. Pat found a desk space in an office space upstairs in a Karate studio in inner Melbourne, while Troy worked out of a cafeteria initially at one of the OEM facilities. They reached out to one of the local installation contractors who they had been using heavily, SONNEX Engineering, and spoke with Jano about his experiences in setting up and running a business. Jano referred them to Matthew Worrell at PFA and Associates, who later went on to open Worrell and Co Accounting. Matt and his team still continue to work with ASA to support accounting functions within the business to this day.

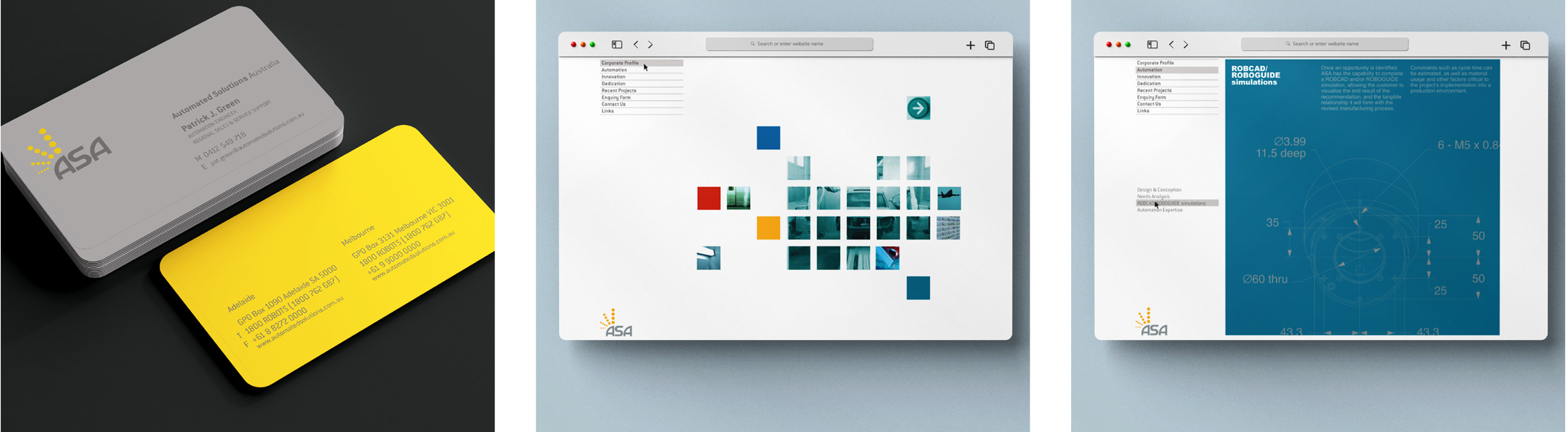

With the company set, and structured, it was time to impose a branding strategy. The FANUC brand, who ASA were aligned with in terms of servicing and support, had a strong yellow brand image in their logo. However, the paint robot, unlike most of the other FANUC robot range, was silver, not yellow. Troy knew of a friend who was working in the UK as a graphic designer and brand keeper, so he engaged him in the process of designing the brand image. The intent was to create an industrial feel, without it being cold, and incorporating the yellow associated with FANUC, as well as the silver of the paint robots, into the brand. The initial design was a business card that appeared as a stainless steel piece of diamond plate. This was veto’d, in lieu of a smooth, slightly textured card, that featured embossed dots above the A, giving a slightly more modern feel.

Along with this brand image came the very first development of a website, specific to paint automation.

Prue Lieberg arranged the company’s international travel in 2003 at the Flight Centre travel agency at Elizabeth Shopping Centre, because of its proximity to the Adelaide headquarters. As with many account managers, she moved on, and on October 23, that year, the team got an email from Alex Prez, who was succeeding Prue at Flight Centre. This started a partnership that has lasted for the past 19 years, with Alex serving as the company’s outsourced travel agent. Alex’s tale is one of a kind, and he lives by the credo “promise low, deliver high.” Alex has collaborated with ASA to provide exceptional travel outcomes for our team, developing an efficient travel management programme for ASA that enables the team to focus on core business operations. Finding a person or company with a development mentality, and collaborating with them to improve and achieve success, is a recurring theme at ASA. Alex is the embodiment of this philosophy.

A year later, it was by a repair on the PC that again promised low, and delivered high, that led to an chance encounter with Michael Boonzaayer. His philosophy was to deliver over and above, and this mentality was exactly what underpins ASA’s core values, as its employees are its strength, and its greatest point of differentiation. Mike was convinced to come aboard and is now in his 18th year at ASA as the Paint Process Supervisor, completing offline work, and directing our Paint team across the globe.

‘Finding a person or company with a development mentality, and collaborating with them to improve and achieve success, is a recurring theme at ASA.’

By 2005, 3 years into its infancy, ASA had grown from 2 to 5 Full Time Equivalent (FTE) employees. In 2005, the company was recognised as a finalist in the Telstra Small Business Awards, as well as the Entrepreneur of the Year program in the Central Region, and the Engineers of Australia Architecture Awards for the 2,500 m2 commercial premises that had been constructed at the GM Supplier Park facility at Edinburgh Parks. The facility was designed for large scale modular builds and customer training. The company was growing.

In parallel to this, the AFSA that Pat was completing in Melbourne was spanning into far more than just paint. Pat was taking free-issued FANUC yellow robots, and installing them onto plastic moulding machines, and machine tools.

In 2006, the team took stock, and organised a retreat where the business plan was reviewed, and the overall strategy revisited.

By 2007, a repeat paint robot customer approached ASA about a robot system for preparation of their plastic moulded parts. This would be a yellow robot system, featuring an M710iC/20L robot. It would be the first fully integrated non-paint system that ASA would provide, and a diversion from the original business model of being specialists, focused on painting and dispensing applications.

In the same year, ASA began working with Okuma through the Melbourne office. ASA would design a bespoke machine tool tending solution for a customer, Okuma would procure the robot that was identified for the system, and ASA would integrate it into the cell, and provide training and support. This was the beginnings of what is now deemed our Australian division, where ASA integrates yellow robot (non-intrinsically safe, general purpose robots) for Australian and New Zealand customers. The model was very successful, and ASA continues to deliver some excellent outcomes for Okuma and other machine tool companies.

In 2008 came the dreaded Global Financial Crisis, or GFC. Significant consequences were noticed in the automobile industry, as capital expenditures were reduced. During the GFC, ASA was extremely fortunate that a large system was already ordered and being built in Australia for one of the OEMs, which was one of only a handful of projects occurring in this market segment around the world at the time. ASA made the deliberate decision to retain its whole staff, despite the lack of projects to bill them against. There was a time when the team stayed in the office for six weeks without any billable tasks, developing training materials in the expectation that this too would pass. And it did. After six weeks, things began to gradually improve.

In the aftermath of the Global Financial Crisis, ASA saw the need to diversify its revenue streams and reduce its dependency on the automotive industry in Australia. This meant two things – the first being a clear and purposeful investment in the expansion of the non-paint sector in Australia. ASA also anticipated that investment in low-volume capital intensive automobile facilities in Australia would likely dry up, even with the great product that was being produced in Australia. This would necessitate a pivot, and that personnel spend more time abroad and concentrate on establishing business offshore in markets such as Asia and the Americas.

As ASA moved into the next decade, ASA continued to grow in the two business streams – supporting overseas paint projects, while growing its non-paint business in Australia. The first half of the decade saw a large number of projects being executed in the Asia-Pacific region, with a large focus on support in China and Korea, while in Australia, ASA began to unlock opportunities with large scale mining tooling companies for turnkey automation systems.

By 2015, ASA had grown to 15 staff, and with it came the expansion into the USA, as Automated Solutions America LLC. ASA LLC facilitated a means for ASA to be recognised as an Authorised System Integrator (ASI) to FANUC America, while allowing ASA to employ personnel state-side for project execution activities on the ground in the USA.

In 2022, ASA opened ASA Defence, and today, the collective ASA group employs over 20 Automation Engineers, programmers, designers and support staff. ASA has offices in Adelaide, Melbourne and Detroit, and has executed multiple projects in Australia, New Zealand, Korea, India, Thailand, China, Malaysia, Mexico, South Africa, Brazil, Argentina, the USA and Canada.

As we celebrate our 20th year in business, we are reminded of all the people we have met and all the customers and partners we have formed deep connection with. Thank you for being part of ASA’s journey over the past 20 years. We value your loyalty and friendship and are extremely excited to continue to work with you, delivering tomorrows solutions today.

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening |

More (Recent) News Stories from Automation Solutions Australia:

Deburring Machines | Robots a Historical Overview | Robotics Engineering | Automatic Paint | Robotic Loading Systems for CNC | Unlocking Your Manufacturing Potential | Spray Painting Robots | Automatic Sandblasting | CNC Mills | Automated Welding | Unlock the Future with Automation Systems | Robot Company, The Automation Era | Choosing an Automation Company | Harness the Power of Robotics with ASA | Robotic Painting | Automotive Welding | The Path to Machine Tool Automation | System Integrator Australia | Robotic Welders | Automate your CNC | Automation Company | Electrical Design | Human Machine Interface | Plastic Paint Robots | PLC Programming | Robotics Australia | Solutions | Industrial/Manufacturing Robots | Industrial Engineering | FANUC Robot | Shot Blasting | Robotic Automation Solutions | Industrial Automation | FANUC Industrial Robots | FANUC Collaborative Robots | FANUC Palletising Robots | Robotic Palletisers | Robotic Fibreglass Spray Machines | CNC Machine Automation | Robotic Arm – An Industry Guide | The Cobot | Automation Robotics | Custom Automation Solutions | Assembly Robots | Automate your Paint Booth | Ceramic Coating – Cerakote | Automotive Automation | Pick and Place Robots | Understanding Industrial Automation | PLC Automation | Arc V Spot Welding | What is Cerakote? | CNC Machines Australia | What is a Robotic Cell | Robotics Systems with ASA | What is ARC Welding? |PLC Controls | Collaborative Robots – What are they? | Welding Automation |