At Automated Solutions Australia, we are able to offer a range of FANUC Material Handling Robots

Automated Material Handling Applications Robots

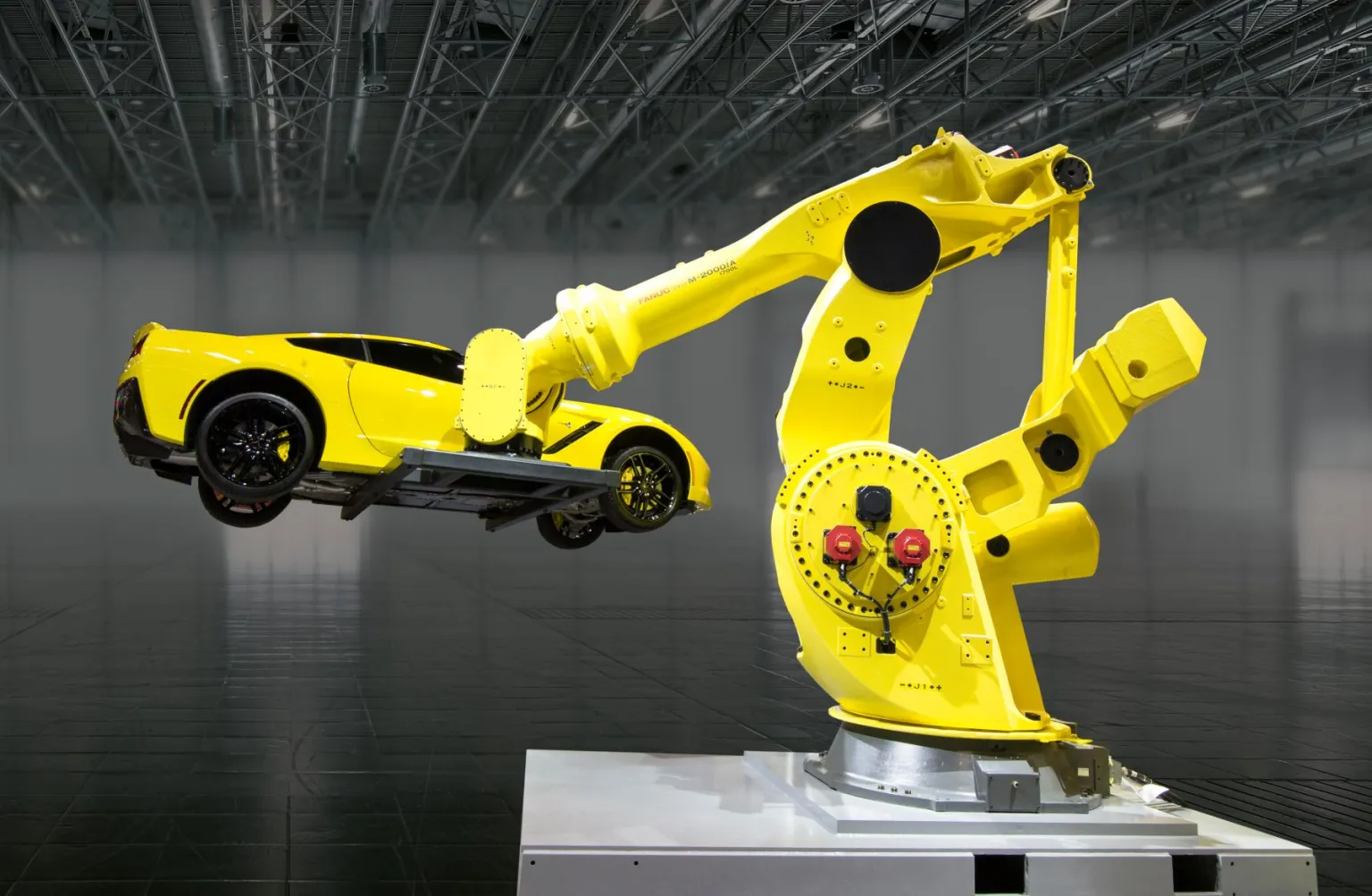

Need to move your components? ASA offers a range of FANUC automated materials handling robots, with payloads up to a whopping 2300 kg. FANUC‘s robot lineup is simply the most robust in the market for material handling and component transfer. They can be outfitted with iRVision and are capable of high-speed transmission in a system that has been thoroughly tuned. It is simple to select a material-handling robot that meets your demands. This is because small robots are built for use in delicate situations and large, robust units for larger applications.

Automated Materials Handling Robots For Every Application

Automated material handling robots are available for every materials handling application. This includes pick and place through to palletising, packing, component transfer, machine maintenance and assembly. ASA can offer standalone solutions or fully integrated systems that automate every material handling operation from the beginning to the conclusion of the production line. Robotic materials handling systems increase production by enhancing throughput and lengthening working periods.

Eliminate Health and Safety Risks with Automated Material Handling Robots

These robots eliminate health and safety risks that arise from picking and placing products repetitively. They are also proven tools for solving tasks where heavy, sharp or hot objects need to be moved on a large scale. The addition of an integrated 2D and 3D vision system allows the robot to “see” the part location, orientation, colour or presence, which can be used for size sorting and quality inspecting as part of the application solution. The addition of a conveyor and encoder allows the robot to identify and track any given part and pick it from a moving conveyor.

Whether you are a large or small manufacturer, if you are looking at Materials handling robots for your manufacturing process, we invite you to contact Automated Solutions Australia to explore the FANUC range today on 1800 ROBOTS. Our industrial engineering team at ASA are FANUC robot specialists, from concept to system designs, installations, programming and support. At Automated Solutions Australia (ASA) we thrive on helping Australian business of all sizes achieve their automation goals, enabling manufacturers to compete on the world stage while building sovereign capability.

Materials Handling Robots:

Collaborative Robots | FANUC LR Mate Series | FANUC M-10 Series FANUC M-2000 Series |

FANUC R-2000 Series FANUC M-20 Series | FANUC M-800 Series | FANUC M-900 Series |

FANUC SCARA Robots |

Send an enquiry:

Click an Application to Explore Further:

FANUC Robots Australia | Paint Robots for Surface Finishing | Welding Robots by FANUC | Machine Tool Tending Robots | Fibreglass and Gelcoat Robots | Palletising Robots | Robotic Vision Inspection Systems | Plastics Painting | Deburring and Polishing | Sealing and Dispensing | Picking and Packaging | Material Removal Robots | Shot Blasting and Peening |

More (Recent) News Stories from Automation Solutions Australia:

Deburring Machines | Robots a Historical Overview | Robotics Engineering | Automatic Paint | Robotic Loading Systems for CNC | Unlocking Your Manufacturing Potential | Spray Painting Robots | Automatic Sandblasting | CNC Mills | Automated Welding | Unlock the Future with Automation Systems | Robot Company, The Automation Era | Choosing an Automation Company | Harness the Power of Robotics with ASA | Robotic Painting | Automotive Welding | The Path to Machine Tool Automation | System Integrator Australia | Robotic Welders | Automate your CNC | Automation Company | Electrical Design | Human Machine Interface | Plastic Paint Robots | PLC Programming | Robotics Australia | Solutions | Industrial/Manufacturing Robots | Industrial Engineering | FANUC Robot | Shot Blasting | Robotic Automation Solutions | Industrial Automation | FANUC Industrial Robots | FANUC Collaborative Robots | FANUC Palletising Robots | Robotic Palletisers | Robotic Fibreglass Spray Machines | CNC Machine Automation | Robotic Arm – An Industry Guide | The Cobot | Automation Robotics | Custom Automation Solutions | Assembly Robots | Automate your Paint Booth | Ceramic Coating – Cerakote | Automotive Automation | Pick and Place Robots | Understanding Industrial Automation | PLC Automation | Arc V Spot Welding | What is Cerakote? | CNC Machines Australia | What is a Robotic Cell | Robotics Systems with ASA | What is ARC Welding? |PLC Controls | Collaborative Robots – What are they? | Welding Automation | Robotic Assembly | Materials Handling | Robotic Welding | History of Robots |